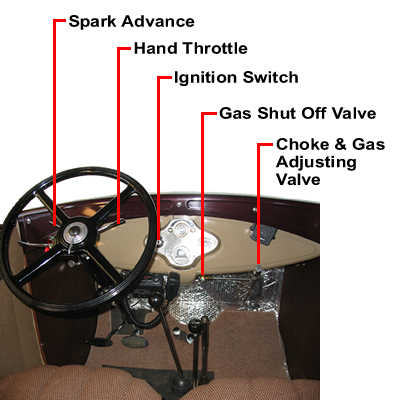

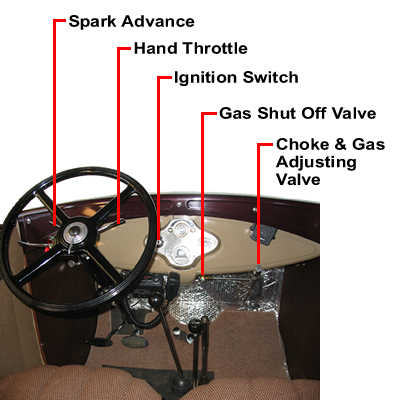

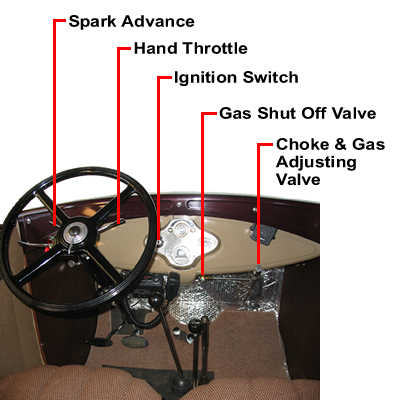

Controls and adjustments to be mastered as you gain experience.

Starting Procedure

- Engage emergency brake by pulling back on it.

- Push lever left of steering wheel (Spark Control) all the way up (Retard)

- Pull lever right of the steering (Hand Throttle) half way down

- Turn Gas Valve under dash on passenger side to open (Pointing down)

- Turn Choke Control Valve (under right side of dash) full clockwise and back off 1/4 turn. If it's quite cold out, it may be better to open a full turn.

- Turn Ignition Switch on (Clockwise)

- Push in clutch and put Transmission in Neutral

- Pull Choke Control Out

- Turn engine over 3 Revolutions – Choke in on 3rd Revolution

- When Engine Starts – Push Throttle Lever (Right Lever) Up

- Put Left Lever all the way down. (Depending on how your engine is timed, 3/4 down might be better.)

- Allow Engine to Warm Up. (The accelerator pedal will need to be used to keep engine running until it warms up.)

- Turn Choke control (actually GAV) clockwise to smoothest operating condition.

- When starting an engine, which is already warmed up, omit Choke steps.

- Always put Left Lever (Spark Retard Position) all the way up when starting & then down when driving.

- Have Fun Driving!

Shut Down Procedure

- Engage emergency brake by pulling back on it.

- Push Left Lever (Spark Control) all the way up (retard position)

- Push Right Lever (Throttle) all the way up

- Turn Gas Valve under dash on passenger side to closed position (pointing to the Left). If vehicle is going to be left over night, or similar circumstances, it's a good idea to let the engine burn up the majority of the gasoline in the carburetor by letting engine run until it stalls.

- Turn Off the Lights and any other Accessory

- Turn Ignition Switch off (Counter Clockwise)

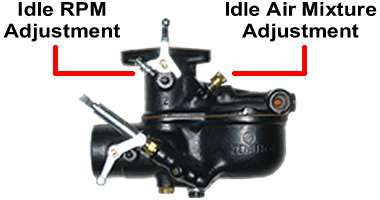

Carburetor Idle RPM and Idle Air Mixture Adjustment

- There are two external carburetor adjustments, and they affect only the idle performance. They are the idle RPM and idle air mixture adjustments

- Turn Gas Valve under dash on passenger side to open (Pointing down)

- Preparation: Fully warm the engine up, move spark control (on left side of steering wheel) up, turn the under dash choke control knob full clockwise and then counter clockwise about one turn, and move the hand throttle lever (on the right side of the steering wheel) all the way up. If engine tend to die, pull the throttle lever down a little.

- Preliminary Idle RPM adjustment: Turn the adjusting screw on the carburetor throttle arm until the end of the threads is making contact with the stop. You should now be able to put the hand throttle lever all the way up without the engine tending to die. Go back to the adjusting screw on the carburetor throttle arm and adjust it to a low RPM, just faster than where engine tends to stall. This will ensure that the carburetor idle circuit if functioning.

- Idle Air mixture adjustment: Slowly turn the idle air mixture screw clockwise until the engine begins to stall, and note the position. Slowly turn the idle air mixture screw counter clockwise until the engine begins to stall and note the position. Now, adjust the screw about half way between the two positions, and you will often hear a very slight increase in engine RPM. (Idle air mixture screw should be about 1–1/2 turns out from full clockwise.)

- Final Idle RPM adjustment: Pull the spark lever about 3/4 down. Readjust the idle RPM adjustment for the idle speed that you prefer. (If adjusted too high, you will likely tend to grind gears when driving.)

Using Carburetor to Check Engine Timing

- Increase engine speed to twice that of idle RPM by pulling down the throttle lever at the steering column.

- Gradually open the gas adjusting valve 1/2 to 1 full turn. The engine should start to run richly, and some smoking at the exhaust may occur. This verifies that the fuel passage, regulated by the Gas Adjusting Valve, is open. Turn the GAV clockwise until the engine RPM returns to where it was previously

- Slowly pull the spark lever down. Engine RPM will increase up to a point. When the maximum RPM is achieved, note this as the position where you will want to place the lever for normal driving purposes.

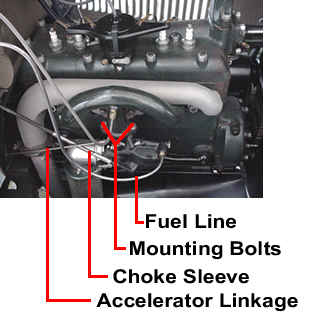

- Raise the throttle lever up to the top of its travel. The engine should idle smoothly. With the spark lever still in its "ideal" position for everyday driving, go around the car to the carburetor and ram the accelerator control rod (i.e., from the accelerator linkage) forward. The engine should accelerate to maximum speed within about two seconds if the engine timing is correct. Don't hold the accelerator rod in this forward position for more than a few seconds, because you could damage your engine. If the engine accelerates smoothly and without stumbling, your idle and ignition settings are correct.

- If acceleration of engine speed is slow or sluggish, ignition timing is probably somewhat retarded. Move the spark rod up to the top of its travel, and adjust the timing. Once the timing has been adjusted, restart the engine, pull down the throttle rod until engine RPM is twice idle RPM, and return to step 3.

Adjusting Engine Timing

- Before adjusting the engine timing, ensure that the breaker point contacts are in good shape and the gap is set to .016 - .020 inches. Also, verify that the rotor gap to the distributor body contact points is between .030 to .035 inches.

- Turn ignition key off.

- Place gear shift lever in neutral position.

- Fully retard spark lever on the steering column.

- Screw out timing pin located in timing gear cover and insert opposite end of pin into the timing pin hole.

- With starting crank, turn the engine over slowly while at the same time pressing in firmly on the timing pin. When the piston #1 reaches the top of the stroke, the timing pin will drop into a small recess in the timing gear.

- Remove the distributor cap, body, and rotor, and loosen the distributor cam locking screw until cam can be turned.

- Connect a test light probe between the breaker point arm and an engine ground.

- Turn ignition switch on.

- Turn cam in counter clockwise direction until the breaker points are fully open (light comes on), then slowly turn the cam back in a clockwise directions until the points just close (light goes off). Next lock the cam by securely tightening the cam locking screw. Be careful not to move cam position, while tightening the screw.

- Slowly pull down on spark advance lever. The test lamp should come on (points open) when the lever is about 3/4 down. Sometimes steps must be repeated until distributor cam is properly set.